Equipment

1. Designing

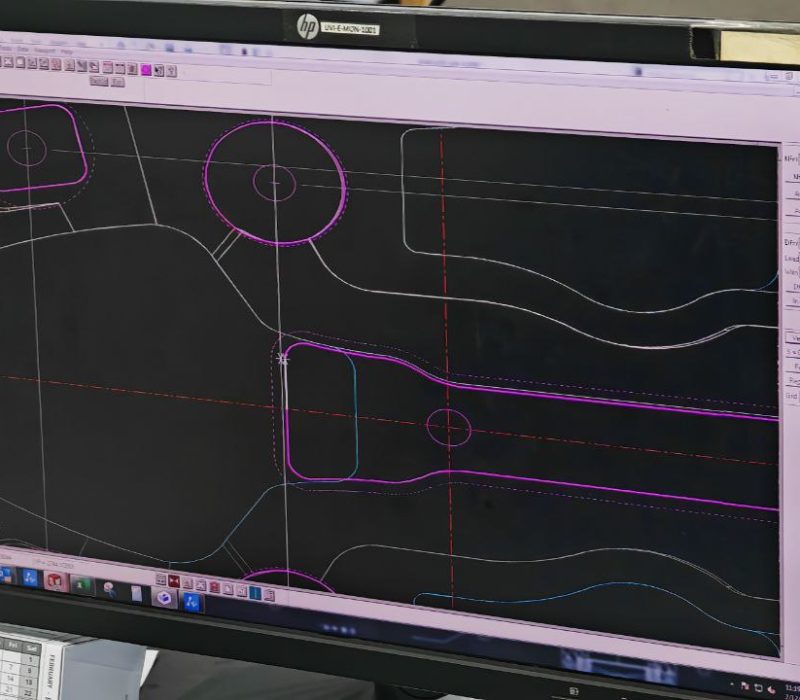

The part is designed using SolidWorks or ZWCAD. Then, tooling is created and adjusted. CAMWorks or Mastercam makes the toolpaths for the CNC machine. Quick Press is used to create the die, and a prototype is tested. Simulations help fix any issues before production.

2. Tooling / Die Assembly

The individual components of the die are made and tested for fit. After that, CAMWorks or Mastercam is used to create toolpaths for CNC machining. The die parts are then assembled, and the complete die is tested to ensure it works correctly.

3. Quality Testing / Improvement

The die or tooling is tested by creating a prototype and checking how it works. If there are any issues, the design is adjusted. After fixing problems, it’s tested again to make sure it works right. Once it’s good, the tooling is ready for production.

4. Mass Production

In mass production, the die or tooling is set up in machines to make lots of parts. Quality is checked regularly, and any problems are fixed. Once everything works well, production continues until parts are made.

Partner with us for cutting-edge manufacturing solutions.

Experience the future of automation and innovation today!